Our Valued Clients

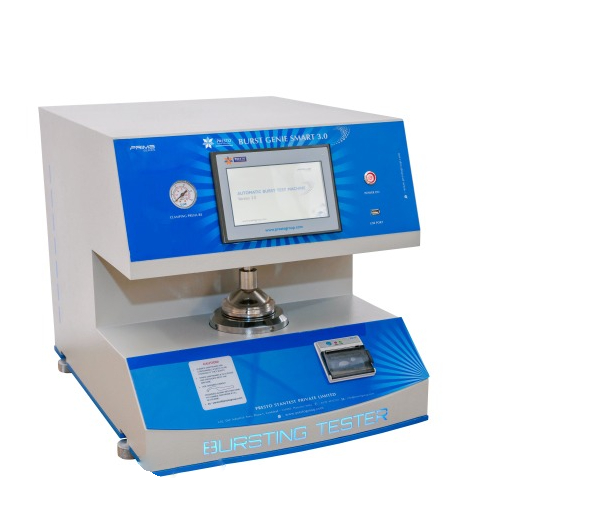

Bursting Strength Tester Genie Smart 3.0 is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene.

Presto Melt Flow Index Tester is used for evaluating the flow properties of molten plastics or resins. The Melt flow Index of thermoplastic materials is defined as the rate of flow (in grams per ten minutes) of extrudates of molten resins through a jet of a particular length and diameter.

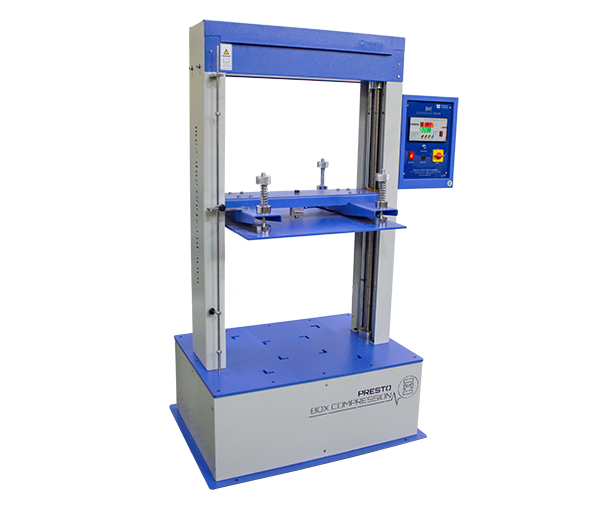

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit. Cardboard boxes are commonly stacked one on top of the other, during warehousing and storage. So, to ensure that they do not collapse during this, it is necessary to measure their box compression strength. It is based on the principle of measuring the maximum load that the material can withstand without breaking. This process is performed by applying a gradually increasing compression force to a sample until it fails using Box Compression Tester.

Using the equipment, a force-deformation curve can be obtained. This curve helps us evaluate the resistance of a package. It is a reliable equipment that provides accurate information regarding the compressive strength and durability of the package. It enables manufacturers to choose a more resistant packaging and to ensure the contents of the package don’t get damaged during stacking or transit.

Thus, corrugated boxes/cartons/paper packaging can be tested using Box Compression tester. It is widely used to determine compressive resistance, deformation and stacking capability of cartons and corrugated boxes.

Registered Design Patent No. 279106

In stock

Magnamike, manufactured by Olympus, is a premium-quality device renowned for its excellence in conducting wall thickness gauge testing. Offering a non-destructive testing method, this instrument is ideal for measuring the wall thickness of PET bottles. Presto Stantest serves as an authorized dealer for this device.

In stock

Presto provides the Polariscope, an exceptionally effective strain viewer designed to assist manufacturers in testing the quality and transparency of their products, thereby ensuring the highest standards of quality assurance for customers. The Polariscope operates on the principle that variations in refractive index indicate differing strain distributions, resulting in reduced material transparency.

Registered Design Patent No. 252609

Presto's Hot Wire Bottle Cutter is a widely used instrument in PET bottle industries. PET bottles are mainly used for packaging of various products such as carbonated drinks, food items and so forth. They are also used for packaging of chemical.

Registered Design Patent No. 252608

The Top Load Tester gives the compressive buckling load in digital format. This is a fully automatic motorized model. The Digital display of the Digital Top Load Tester is aesthetically appealing and sophisticated.

It has the capability of measuring the maximum load a container can withstand without deforming when the force is applied from the top.

A Top Load Tester plays a major role in testing strength of items like bottles, containers, jars or packaging materials. It will help you avoid transit issue. You will be able to restrain deformation and defects while storage, shipping and transportation. A Top load tester is widely accepted in various industries like bottling manufacturing, filling and beverage etc. It is a proven method to avoid rejections and leave a perfect impression on your customers.

Registered Design Patent No. 279112

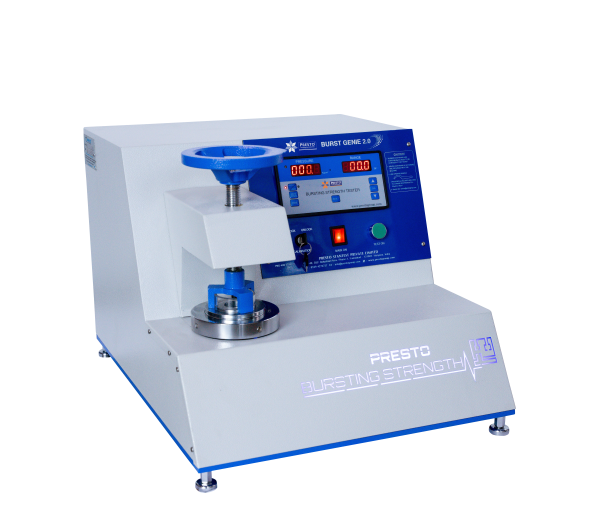

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the material's quality as compared to the others. Bursting Strength Tester Genie 2.0 provides a hydraulic pressure on the sample.

In the Presto Bursting Strength Tester, a hydraulic pressure is applied on the sample under test, using a neoprene diaphragm, on a circular area. So, a circular piece of the sample of the corrugated board is used for the test. A digital indicator with a range of 0 to 40 kg/ square cm, is utilized for the equipment.

Registered Design Patent No. 279109

Availability: In stock

.png)

Presto Edge Crush tester - Digital (ECT) is rugged enough for any production testing environment. It is the ideal testing equipment for paper making, packaging, quality inspection department and more.

Availability: In stock

Salt Spray Chamber is made as per ASTM B117 and JIS 2371 which is used for conducting Neutral Salt Spray Test or NSS test on Meta Surface Coatings. It is used for checking the resistance of the coating towards corrosive environment. The Salt Spray Tester generates an accelerated form of Salt laden environment inside which the specimen are tested for its quality.

Our Salt Spray Chambers come with three different types of specimen-holding fixtures. Those are as follows:

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

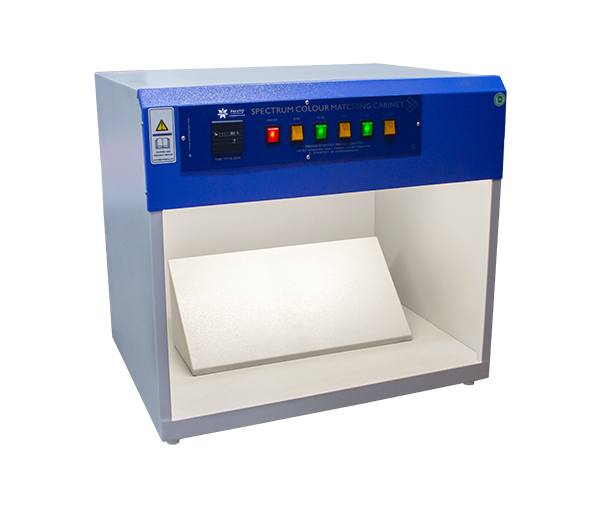

The Presto Color Matching Cabinet Spectrum Asia II is one of the widely used lab testing instrument in the industries and laboratories where it is important to maintain the color consistency of the products. This color matching machine will provide accurate assessment of colors under standardized environment for evaluation and visual assessment of colors.

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films.

Availability: In Stock

Shipping Area: Throughout the world

Presto Adhesion Strength Tester is used to quantify the permanence of adhesion or peel ability of self- adhesive pressure sensitive materials. Peel adhesion is defined as the force required for removing a pressure sensitive coated material.

Peel Bond Strength Digital Tester is a standardized test machine, which is widely used to conduct accurate peel/seal strength test for adhesive materials. Suitable for measuring the stability of adhesives like tape or glue, it is a reliable quality control equipment. It is used for checking the ability of the sample to get peeled off from a surface. The testing equipment is designed and manufactured according to ASTM D903 standard.

Presto Peel Strength Tester has a display screen which is based on a hi-tech microprocessor that converts force applied into numeric values. So, the peel adhesive strength value that is measured can be directly viewed on the screen. Application force is controlled uniformly; this is done in order to ensure equal distribution of pressure, all over the test sample.

Registered Design No. 361206-003

Availability: In stock

Quality testing is important because it helps ensure that products are safe and reliable. It can also help identify potential problems early on before they cause serious damage or injuries. Quality testing can also improve customer satisfaction by ensuring that products meet their expectations. Thus, if you are searching for the best quality testing instruments in Egypt then you can go with Presto Quality Testing Instruments.