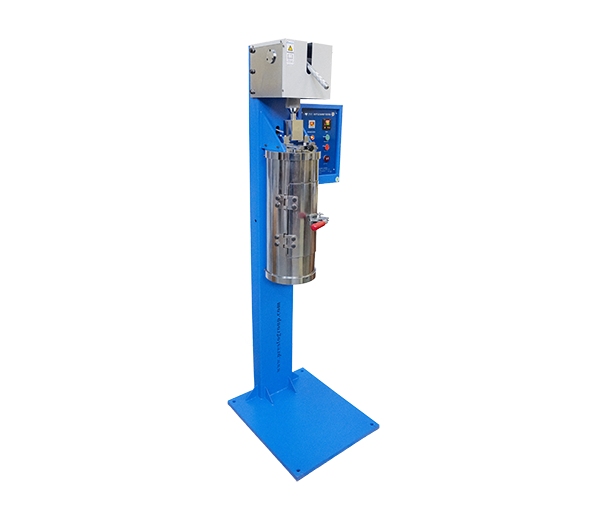

A Digital Bottle Burst Tester is used in PET bottle industries to test the strength of the bottles against bursting. For PET industries, it is important to provide best quality bottles to the bottling plants so that the best safety of the products could be ensured with proper quality testing.

Registered Design Patent No. 279110

Tensile testing is an important process for evaluating the strength, ductility, and toughness of materials. By determining a material's Young's modulus, tensile testing can also provide information about a material's stiffness.

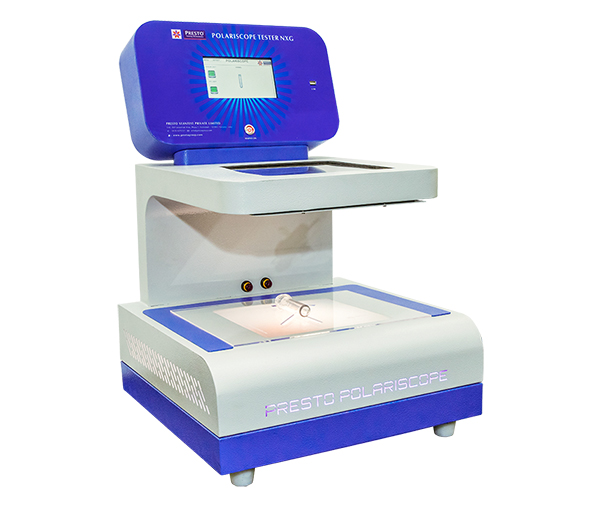

Different defects like cracks and strains present in PET & preform products may affect their quality. Testing these defects will help the manufacturers to gain confidence in their product quality. Presto has designed a high-quality lab testing instrument known as Polariscope Strain Viewer-NXG.

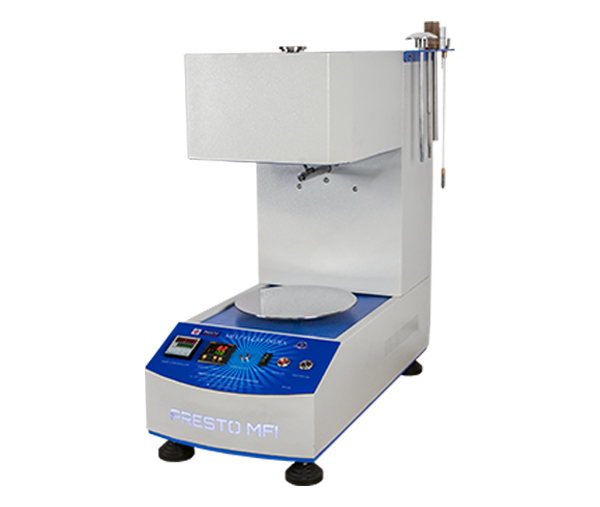

The melt flow rate of the polymers is one of the essential properties of the materials that will help the manufacturers in determining the rate at which it flows. This property of the material is important as it provides the necessary data on the mass flow rate of the polymer. Thus, to test the melt flow properties of the materials, we at Presto have recently designed a high-quality Melt Flow Index Junior model.

The new-design MFR Model can quickly extrude the flow rate of molten resins utilizing the advanced setup of load, piston, and a metallic barrel. The specimen, majorly in granule form is put inside the barrel and the piston is inserted. Loads, as per requirement are placed on the piston and the parameters are then selected from the touchscreen display.

Top load testing machine is widely used in Plastic bottle vertical in order to determine the resistance strength of bottle under increasing vertical compressive load. The equipment is a digital version model and can precisely imitate the compression load utilizing straight inverted plates. The test aftereffects can be visually checked on the specimen post-test. Get the best test solution for PET bottles with Top Load Tester in Pune, Maharashtra. We also cater to international countries with testing instruments.

Polariscope Strain Viewer computerised is utilized for conducting quality and transparency test. It is used to identify and evaluate residual strain in PET preforms, bottles and similar products.

l 600.png)

Presto Vacuum leak detection system is now available in Prima series. With HMI Touch Screen Display and fully automatic controls, one can ensure accuracy with repeatability and take data acquisition for the various tests. The Vacuum Tank is specially designed to conduct leak integrity testing of large sized packages in any of the testing mediums.

Inspecting the wall Thickness of Plastic Bottles is an important property that helps to measure the quality of the PET bottles and preforms. To solve this requirement of testing, Presto offers premium quality of Magna-Mike 8600.

Cap Pullout tester is used to determine the maximum pull-out strength which is required to pull out the cap of the bottles. It is an important principle used to ensure the quality and the strength of the cap of the bottles.

The Presto Fill Height Syringe is a valuable laboratory tool that can save time and improve accuracy during the container fill height and volume measurements.

Base Clearance Membrane and Vault Control Unit is a consistent tool that helps the manufacturer in measuring the depth of the base of PET preforms and bottles. It is based on the principle to test the accuracy of the shape and size of preforms and determine stability.

Registered Design Patent No. 279107

Presto's Bottle shaker or G V Shaker is a mechanical and motorized testing instrument used to automate the shaking of bottle specimens to stimulate the carbon dioxide, present in the test specimen.

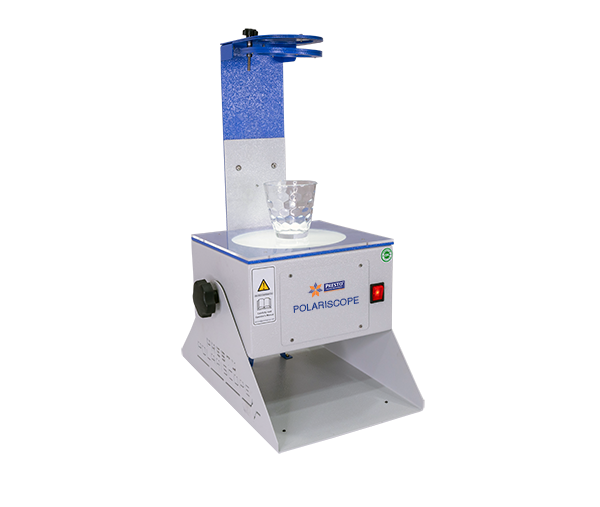

Presto's Glass & Plastic Polariscope - Strain Viewer is the best and highly effective testing device which is used to measure the residual stresses and strains that are introduced during the manufacturing process of the products that severely affects the strength of the product.

Torque Tester - Analogue is a consistent tool to measure the force or torque required to open a closed cap of PET bottle/Jars. It gives Torque in analog format. The analogue display is a high-end sophisticated read out with pointer adjusting knob.

Heat Deformation - HDT/VSP Tester is a consistent tool useful for determining the ability of a given polymer to bear load at elevated temperatures. Accurate and reliable deflection or deformation is an important component in the plastics industry.

Bottle Burst Tester is a consistent tool used to perform Bottle burst test on PET bottles with minimum pressure and check the volume expansion of test samples. The testing instrument Bottle Burst Tester - Touch screen is used to measure the Burst Strength of PET bottles when subject to pressurized air.

Registered Design Patent No. 252612

In stock

Presto's Hot Wire Bottle Cutter is a widely used instrument in PET bottle industries. PET bottles are mainly used for packaging of various products such as carbonated drinks, food items and so forth. They are also used for packaging of chemical.

Registered Design Patent No. 252608

Presto provides the Polariscope, an exceptionally effective strain viewer designed to assist manufacturers in testing the quality and transparency of their products, thereby ensuring the highest standards of quality assurance for customers. The Polariscope operates on the principle that variations in refractive index indicate differing strain distributions, resulting in reduced material transparency.

Registered Design Patent No. 252609

The Digital Eco Vacuum Leak Tester is a cost-effective and efficient testing solution designed to enhance the quality control processes in your packaging applications. Crafted with exceptional precision, this laboratory testing equipment is tailor-made for the accurate detection of leaks in a diverse range of packaging materials. Proficient in examining a wide array of items such as foiled cups, gels, grains, cereal, bakery products, confectionery items, frozen foods, cheese, medical supplies, and pharmaceutical products, the Digital Eco Vacuum Leak Tester is your go-to solution. Whether you need a vacuum leakage tester for testing your food packets against vacuum leakage or you want to preserve the integrity of your packaging then you must go for our vacuum testing machine.

The Top Load Tester gives the compressive buckling load in digital format. This is a fully automatic motorized model. The Digital display of the Digital Top Load Tester is aesthetically appealing and sophisticated.

It has the capability of measuring the maximum load a container can withstand without deforming when the force is applied from the top.

A Top Load Tester plays a major role in testing strength of items like bottles, containers, jars or packaging materials. It will help you avoid transit issue. You will be able to restrain deformation and defects while storage, shipping and transportation. A Top load tester is widely accepted in various industries like bottling manufacturing, filling and beverage etc. It is a proven method to avoid rejections and leave a perfect impression on your customers.

Registered Design Patent No. 279112

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

The new generation Top Load Tester - Prima Series for PET bottles and jars is a fully automatic motorized device that helps to generate compressive buckling load on the products. The instrument offers compressive buckling load on Human Machine Interface based Touchscreen display.

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock

The Specific gravity of any elastomer is of considerable importance for its identification and can also be used for providing a rough assessment of its physical properties.

Presto's Profile Projector is robust measuring testing equipment which is widely used in PET & Preform Industries, quality assurance departments, machine shops and also in industrial testing laboratories.

Magnamike, manufactured by Olympus, is a premium-quality device renowned for its excellence in conducting wall thickness gauge testing. Offering a non-destructive testing method, this instrument is ideal for measuring the wall thickness of PET bottles. Presto Stantest serves as an authorized dealer for this device.

In stock

The Presto Melt Flow Index Tester - NXG Model is a reliable instrument used for evaluating and analyzing the flow properties of molten plastics or resins. The determination of the melt flow index of plastic materials is an important parameter in the evaluation of its quality.

Presto Melt Flow Index Tester is used for evaluating the flow properties of molten plastics or resins. The Melt flow Index of thermoplastic materials is defined as the rate of flow (in grams per ten minutes) of extrudates of molten resins through a jet of a particular length and diameter.

Stretch blown molding industry is mainly involved in manufacturing of plastic products that are used in packaging and bottling industries.