Our Valued Clients

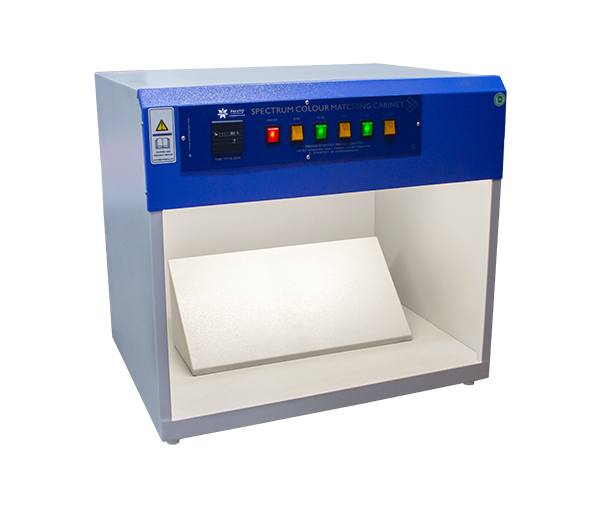

The Presto Color Matching Cabinet Spectrum Asia II is one of the widely used lab testing instrument in the industries and laboratories where it is important to maintain the color consistency of the products. This color matching machine will provide accurate assessment of colors under standardized environment for evaluation and visual assessment of colors.

Cone Crush Tester (Digital Model) is a highly proficient machine which is utilized for calculating the crushing strength of cardboard cones, paper tubes, bobbins and other core packaging material. The working mechanism of the instrument is based on the radial crush testing method.

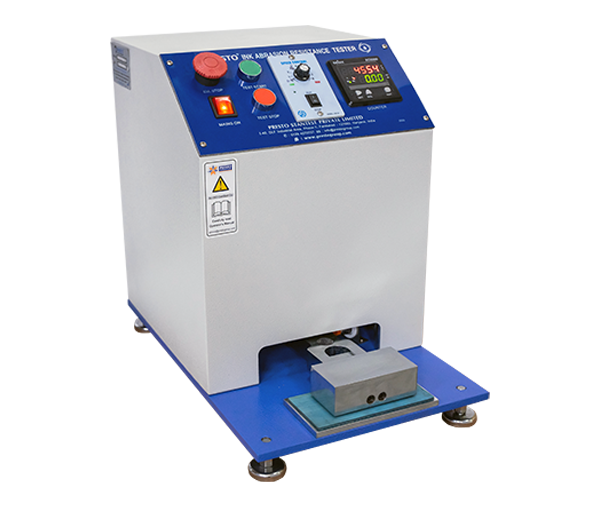

Checking the ink abrasion resistance of a printed material sometimes becomes an intricate task. A lot of precision is required to get the exact estimation. Presto has designed an innovative instrument to check the abrasion resistance of an ink when exposed to extreme conditions. This instrument is perfect for every industry that deals with printing or used printed materials.

The Digital Eco Vacuum Leak Tester is a cost-effective and efficient testing solution designed to enhance the quality control processes in your packaging applications. Crafted with exceptional precision, this laboratory testing equipment is tailor-made for the accurate detection of leaks in a diverse range of packaging materials. Proficient in examining a wide array of items such as foiled cups, gels, grains, cereal, bakery products, confectionery items, frozen foods, cheese, medical supplies, and pharmaceutical products, the Digital Eco Vacuum Leak Tester is your go-to solution. Whether you need a vacuum leakage tester for testing your food packets against vacuum leakage or you want to preserve the integrity of your packaging then you must go for our vacuum testing machine.

The Tensile testing Machine is highly recommended for evaluating the tensile strength of products and materials. The equipment is based on the Constant Rate of Traverse (CRT) principle. It is equipped with an upper jaw and a lower jaw. Universal Tensile Testing Machine is a reliable piece of equipment which is widely used for checking tensile strength of a product/sample. One of the most common mechanical testing techniques used to determine tensile strength, this is a method wherein controlled tension is applied to a sample until it fully fails.

Thus, the material properties of the sample can be easily determined by this test. It involves measuring the force required to elongate a sample under test to breaking point. Using this test, manufacturers and quality managers are able to determine the core strength of their products.

Registered Design Patent No. 252611

Availability: In stock

.png)

The Presto Dart Impact Tester is used for determining the impact of a free falling dart on a plastic film. The energy of the falling dart causes the film to fail under specified conditions. The dart has a hemispherical head and is held by a strong electromagnetic dart holder.

In stock

Heat Sealer Prima is a consistent tool used to perform sealing on flexible packaging products and other thermoplastic materials using pressure and heat by maintaining high temperatures. A heat sealer is used to measure the heat seal performance of composite films.

Availability: In Stock

Shipping Area: Throughout the world

Presto Adhesion Strength Tester is used to quantify the permanence of adhesion or peel ability of self- adhesive pressure sensitive materials. Peel adhesion is defined as the force required for removing a pressure sensitive coated material.

Peel Bond Strength Digital Tester is a standardized test machine, which is widely used to conduct accurate peel/seal strength test for adhesive materials. Suitable for measuring the stability of adhesives like tape or glue, it is a reliable quality control equipment. It is used for checking the ability of the sample to get peeled off from a surface. The testing equipment is designed and manufactured according to ASTM D903 standard.

Presto Peel Strength Tester has a display screen which is based on a hi-tech microprocessor that converts force applied into numeric values. So, the peel adhesive strength value that is measured can be directly viewed on the screen. Application force is controlled uniformly; this is done in order to ensure equal distribution of pressure, all over the test sample.

Registered Design No. 361206-003

Availability: In stock

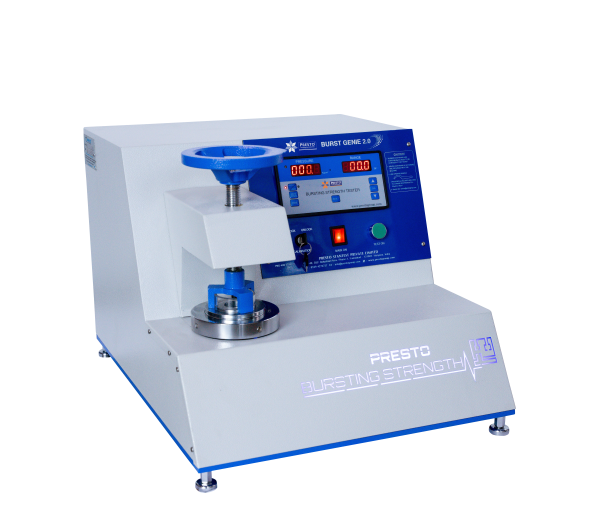

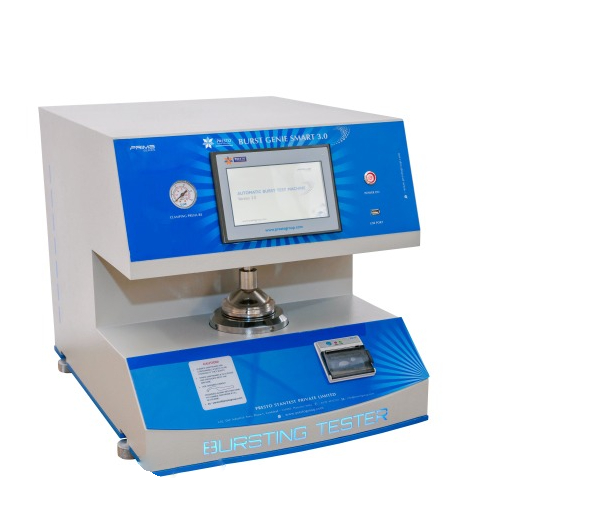

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the material's quality as compared to the others. Bursting Strength Tester Genie 2.0 provides a hydraulic pressure on the sample.

In the Presto Bursting Strength Tester, a hydraulic pressure is applied on the sample under test, using a neoprene diaphragm, on a circular area. So, a circular piece of the sample of the corrugated board is used for the test. A digital indicator with a range of 0 to 40 kg/ square cm, is utilized for the equipment.

Registered Design Patent No. 279109

Availability: In stock

Cobb sizing tester is used for fast determination of the quantity of water absorbed by a paper or board in a given time. The Water absorptiveness (Cobb value) of a substance is defined as the mass of water absorbed in a specific time by a 1 sq. meter...

Vibration simulation is an efficient and cost-effective way of determining damage caused by the repetitive movement in the vehicles. In just a few hours we can pinpoint potential damage areas in your package or product caused by vibration.

Our Vibration Table is customizable. You can get a Digital, Computerised, or touchscreen Vibration table according to your sample testing needs! Be it swivel, synchronous, or asynchronous, test your sample to its fullest to ensure durability, long life, and zero rejections.

Availability: In stock

The Drop Tester (As per IS:7028 Pt IV) is a useful equipment for ascertaining the transport worthiness of corrugated & solid fiber boxes and shipping containers. It has provision with angular drop arrangement to help accurately ascertain the transport worthiness of the package from all angles.

In stock

The quality of the paper and linear boards is determined by its resistance to bending. Presto's stiff resistance tester is designed to test the quality of paper by estimating its resistance. This decides the economic value of the paper. The instrument complies with the testing standards of TAPPI - T489 OM-08. This is the perfect instrument to measure the flexural rigidity of the paper and linear boards or paper boards.

The term scuffing is the rubbing of two materials against each other. Scuff Resistance Tester is used to evaluate the rub resistance (i.e. the damage which has taken place through rubbing) of labels and general printed matter.

In stock

The Presto grammage checking kit comprises of the GSM round cutter along with Digital weighing balance. GSM round cutter with imported industrial blades gives you a very accurate & seamless cutting of your samples.

.png)

Presto Edge Crush tester - Digital (ECT) is rugged enough for any production testing environment. It is the ideal testing equipment for paper making, packaging, quality inspection department and more.

Availability: In stock

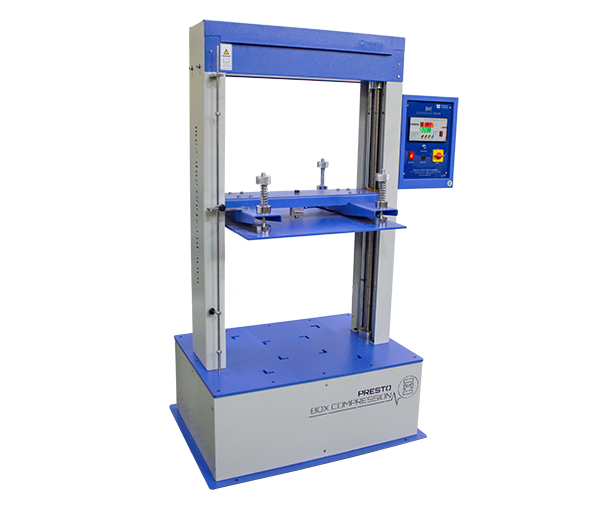

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit. Cardboard boxes are commonly stacked one on top of the other, during warehousing and storage. So, to ensure that they do not collapse during this, it is necessary to measure their box compression strength. It is based on the principle of measuring the maximum load that the material can withstand without breaking. This process is performed by applying a gradually increasing compression force to a sample until it fails using Box Compression Tester.

Using the equipment, a force-deformation curve can be obtained. This curve helps us evaluate the resistance of a package. It is a reliable equipment that provides accurate information regarding the compressive strength and durability of the package. It enables manufacturers to choose a more resistant packaging and to ensure the contents of the package don’t get damaged during stacking or transit.

Thus, corrugated boxes/cartons/paper packaging can be tested using Box Compression tester. It is widely used to determine compressive resistance, deformation and stacking capability of cartons and corrugated boxes.

Registered Design Patent No. 279106

In stock

Bursting Strength Tester Genie Smart 3.0 is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene.

Bible Paper Testing Instruments